GIM WINDER AND TYPE V VESSEL

Manufacture lighter & stronger structures up to 80% reduction in wall thicknesses to reduce manufacturing cost & reduced emissions. Faster and easier to produce. Accurate winding of intricate shapes with 50-micron resolution. High-speed AI inspection for consistent superior quality. In-line graphene coating of fibers for enhanced hydrogen resistance

GIM Winder manufacturers Type IV & V impermeable pressure vessels for clean energy and other industries including automotive, sports, green energy and drones .

5x Lighter than steel Stronger and rigid

Durable

Low permeability

Optimised parts

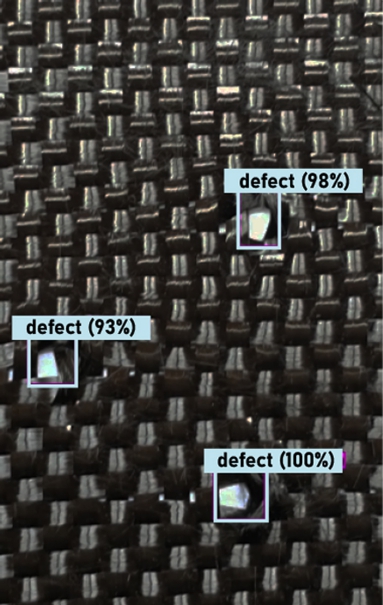

4K AI Quality Checking System for ensuring consistent and superior quality

AI Quality Checking system follows the winding on the mandrel live. Defects and voids are detected instantly, resulting in excellent time efficiency and consistent high-quality winding on all mandrel

GIM CONCRETE

Rapid construction, fast curing, no cement, no water, reduced CO2, Less Energy, recycled materials enhanced with graphene, on track to net zero

Enabling IoT Roads, Infrastructure and Sustainable Smart Cities.

Origional GIM Concrete

GIM Colour Changing Concrete

GIM Carbon Negative Concrete

GIM PPE

Smart Personal Protective Equipment (PPE) for workers health and security care

GIM smart sensors monitor

Heart Rate

GPS Location

Oxygen

Body Temperature

Blood Pressure

Humidity

Excess heat during work is an occupational health risk; it restricts workers’ physical functions and capabilities, work capacity and thus, productivity. In extreme cases it can lead to heatstroke, which can be fatal

By incorporating Graphene, the garment’s weight is significantly reduced while also facilitating effective heat dissipation. Moreover, the use of Graphene renders the garment flame-resistant, impervious to chemicals, and offers superior flexibility. In addition, it provides reliable protection against harmful UV radiation